Attention to detail

It is good quality when the customer feel professionalism in his racing preparation. Our mindset is not limited to producing shiny objects, but encompasses also maintainability, reliability and easy of use in stressfull race situations.

Composit technology

Our hulls are produced with Aero quality fibres and epoxy in mirror finish moulds. We do not use industrial quality matting or polyester resin. A vast improvement over hand lay-ups with chopped strand matting is vacuum infusion of the epoxy into fibre weaves. This process extracts all pores of air from the laminate and increases the fibre content by 90% or more. The fibres are the strength building core of the laminate, vacuum injection yields almost twice the amount of fibre per kilogram of boat. The parts are heat cured for maximum strength of the matrix. The top and bottom halves are joined with a hidden overlapping double joint that can be painted over without the paint cracking in the seam. The transom is double and the stringers come preinstalled by vacuum and seamless weave. Our process is the frontier of composit technology.

Moulds

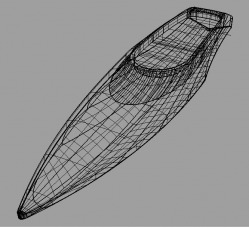

The hulls are designed in a three dimensional CAD environment for optimum strength, performance and aesthetic elegance. The design drawing is transferred by a CAM code to a precision ABB robot that sculpts the plug from a solid block, this ensures a perfectly true plug. After polishing, epoxy moulds are cast from the plugs. Epoxy distorts far less than polyester, thus producing more accurate moulds.

| video0077.3gp |